Material handling allows for the connection of multiple CNC machines. It keeps material flowing through the shop and allows fabricators expand their business. The Advantage-2 highspeed drill line processes 150 tons steel per 40 hour workweek. The ideal drill for small to large fabrication companies all over the world. All stops. Voortman has made the success for the steel industry his number one priority. Because of this, our support and service is unparalleled. Ask for a demonstration, quote, visit, or phone to learn more about some of the most formidable steel fabrication machinery. Voortman has more strength than steel.

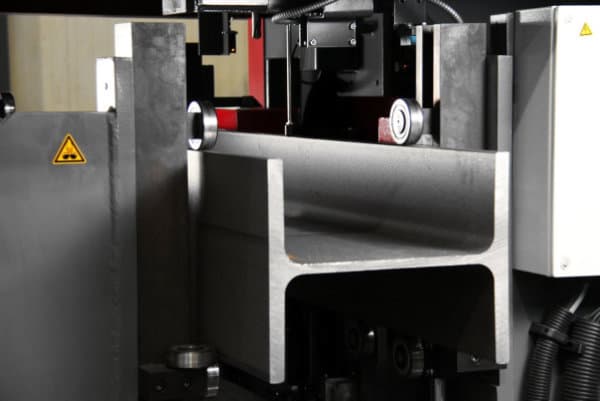

Voortman-designed beam drilling lines have intelligence not only in their own capabilities but also in the fact that they can be plugged into any environment because of their modularity. Tandem solutions, such as band saws with robotic coppers or PeddiWriters, expand the shop�s throughput positioning. It allows for a more cost-effective approach when the steel sector cools down and a more aggressive one when it heats. Voortman invented the Multmaster, which can be used to advance small parts into a tandem-bandsaw. Fabricators are more profitable when they use the whole profile and minimize the remnant. Do you want more output? Check. Material handling is key to any Voortman CNC drill-line profit. Fabricators not only lose money when a profile is manually moved but material handling is far safer than using fork trucks and cranes to move the largest profiles.